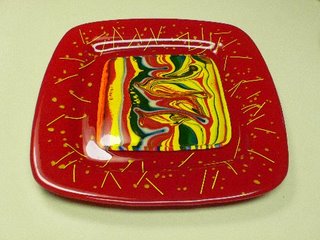

Combing is an exciting technique in glass fusing. Here are pictures of one easy way to do it. First you line 1/8" fiber blanket on the inner edges of one of my stainless steel rings or squares and place it on a well kiln washed shelf. Next you cut strips of 3/8" glass in the color of your choice and line them up in the form on their side. This will give you a nice 3/8" thick combed slab when you are done. As you can see in the picture the strips are tightly packed in the tray. I usually add a few kiln stilts to jam the tray tightly in the kiln. Think about which way you want your design combed and place the shelf accordingly. It is easiest to rake towards yourself pulling the glass from the rear to the front. Heat your kiln until the glass is fully melted. When I use System 96 I heat the kiln to about 1630 degrees. Use good heat resistant gloves. Turn the kiln off, prop the lid maybe 10-12" with a stilt and quickly comb the glass with a glass rake. Don't go too deep as you do not want to disturb the kiln wash. Quench the rake in a bucket of cold water every couple of pulls so that it doesn't get too hot. When the glass is no longer pliable close the kiln and heat it back up and start again. Repeat this process until you have the desired look for your project. The final piece can be used as is or cut up with a tile saw into elements for a larger project. Above is a sample of an 8 x 8" combing being used as a center of a larger piece. Always anneal carefully remembering that this is a thick piece of glass.

My stainless steel rings in different sizes are available at http://bonnydoonfusedglasstools.com